Automated Downtime Tracking Solution

Introduction

Asset-intensive organizations continue to invest in new and innovative ways to manage their assets. The goals are to improve productivity and reliability while reducing costs in a safe and sustainable manner. At the center of their efforts are enterprise asset management (EAM) systems such as Magnus Reactor which helps organizations truly optimize the performance of their assets.

Technological advancement

EAM has been integral to the transformation of asset management for several decades, but these systems have recently undergone their own transformation by embracing technologies such as cloud and artificial intelligence (AI). This is bringing many organizations closer to greater operational efficiency.

About BMI Monier

BMI Monier is the only solutions provider and manufacturer of both flat and pitched roofing in Malaysia. With decades of experience under their belts, they are dedicated in helping customers with all their roofing needs. From residential to commercial buildings, BMI Monier reliable solutions allows them to build roofs that are so much more.

Elevating Roof Performance

As the largest roofing manufacturer in the region specialising in pitched and flat roofs, BMI Monier redefine roofing solutions to meet current and emerging market demands.

Background

As a prominent rooftile manufacturer BMI Monier strives to maintain its reputation for high-quality products and efficient production processes. However, like many manufacturing companies, they faces challenges in asset management especially downtime tracking, which affects its production capacity and profitability. To address this challenge, we propose a digital downtime tracking solution that will help BMI Monier improve its production capacity and profitability.

Problem Statement

Downtime can be defined as the time when the production line is not running due to unplanned maintenance, equipment failure, or other issues. The consequences of downtime can be significant, including decreased production capacity, increased operational costs, and lower profitability.

Obstacle

BMI Monier experiences downtime contributed by a lack of proper tracking and analysis of the downtime causes, which leads to difficulty in taking corrective actions.

Digital Downtime Tracking Solution

Our proposed digital downtime tracking solution will help BMI Monier address its downtime challenges by providing real-time tracking and analysis of downtime causes. The solution can use sensors and data analytics to track downtime events and identify their root causes, enabling BMI Monier to take corrective actions quickly and effectively.

Overview of Magnus Reactor

Benefits

- 28.3% increase in the productivity of maintenance

- 20.1% reduction in equipment downtime

- 17.8% decrease in inventory maintenance and repair

Magnus Reactor is an integrated and configurable enterprise asset management application to automate workflows, provide analytic tools, and manage content. It leverages embedded AI, using both supervised and unsupervised machine learning to uncover insights, and supplies low-code capabilities.

| Magnus Reactor capabilities | |

|---|---|

| Inventory management | |

| Industrial IoT platform | |

| Safety management | |

| Work order management | |

| Health monitoring | |

| Data analytics | |

| Multicloud deployment |

Application features

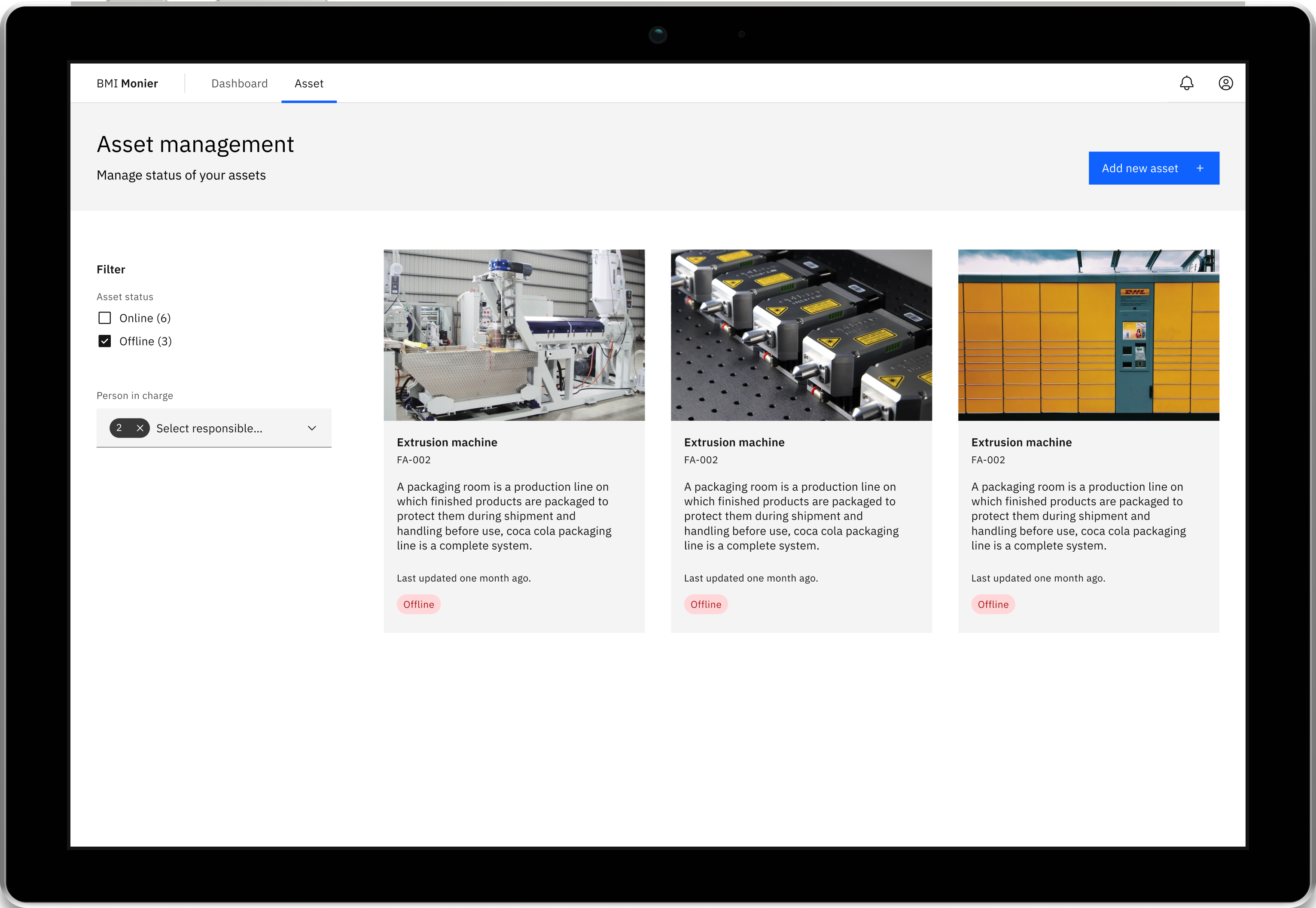

The application will have the following features:

- Asset database

- Asset hierarchy

- Asset details

- Online/offline selector

- Downtime analysis

- Reports and dashboards

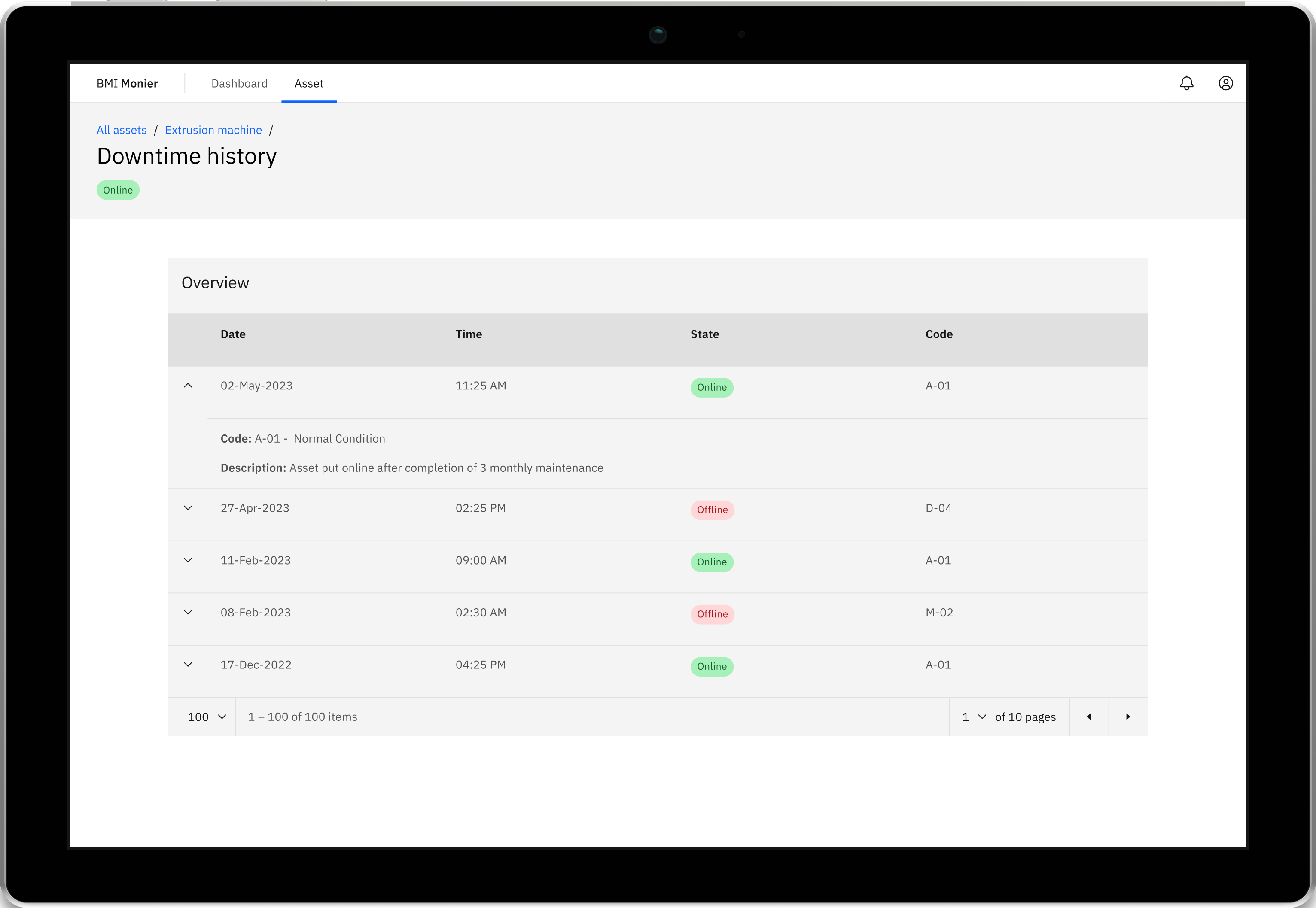

- Downtime history

Tracking Downtime

Downtime can be tracked by manual input or integrating the asset through IoT platform (Magnus Iot Edge). The workflow for downtime detection will be as follows:

Application workflow

Asset

A database of assets will be created and displayed through a user interface. Users will be able to add, view and edit asset details such as name, location, warranty, serial number etc.

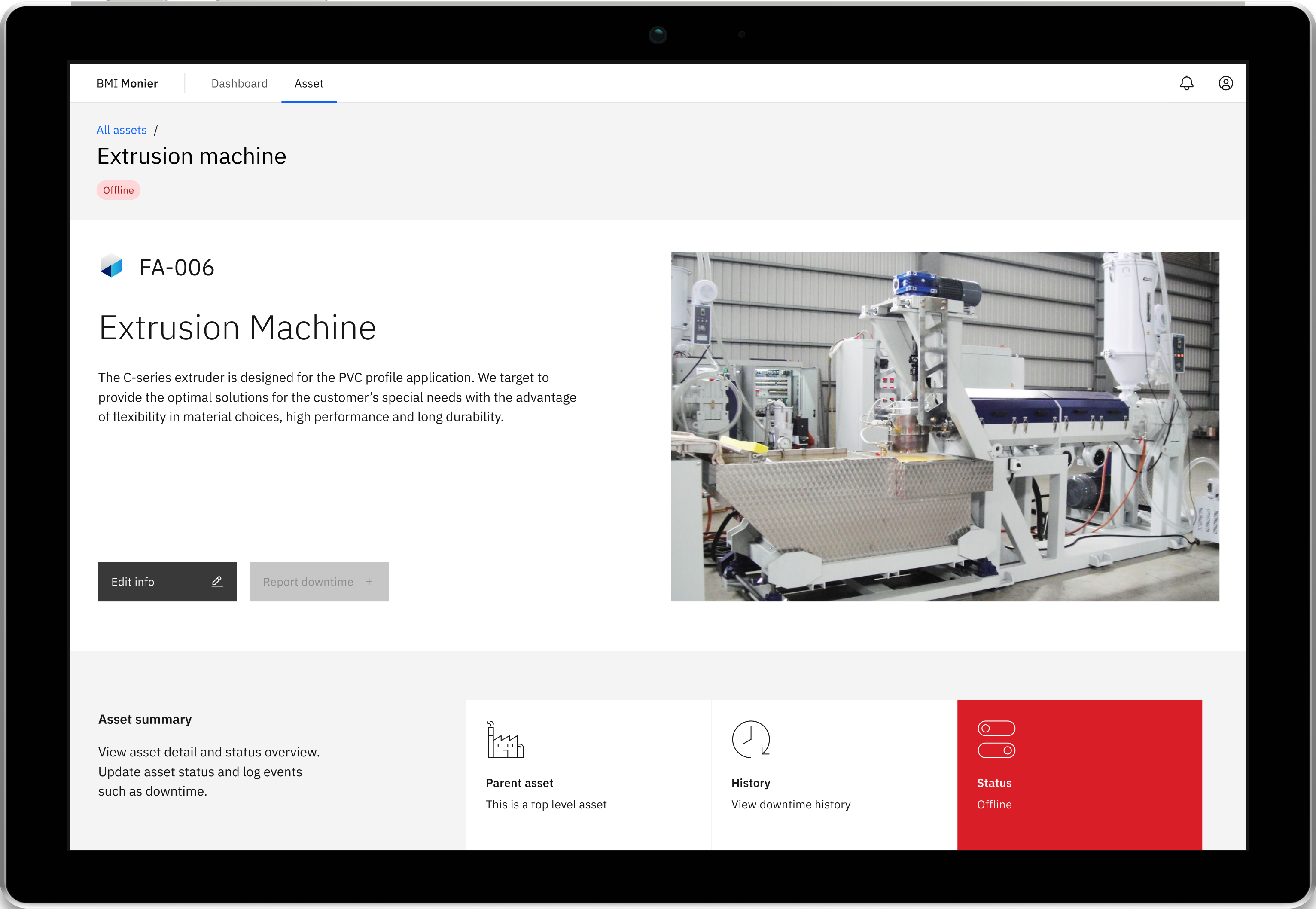

Asset Details

From the asset details page, the user will have the overview of all info related to the asset including the asset hierarchy associated with it.

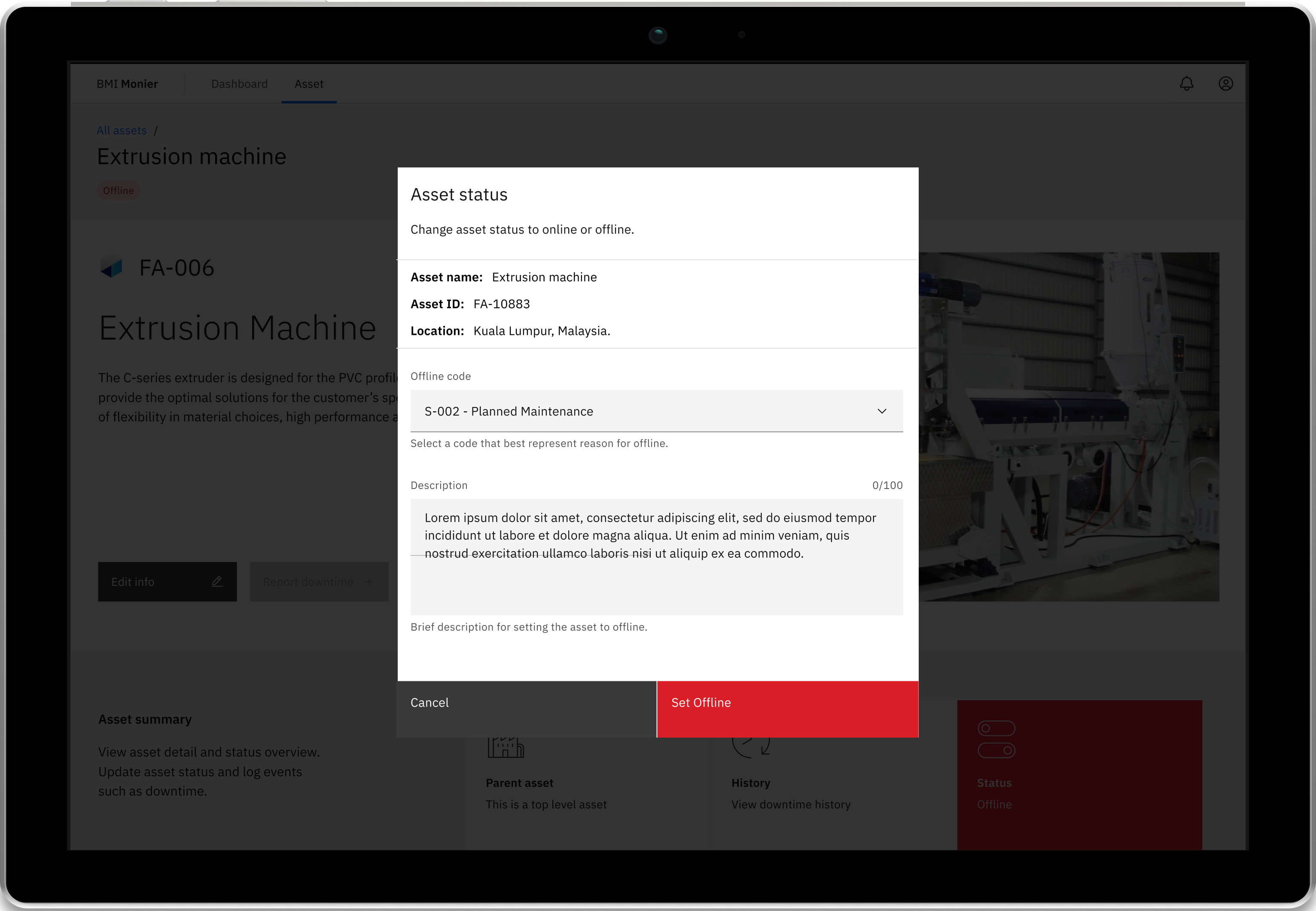

Downtime Entry

The user will have the ability to put the equipment online or offline and assign downtime category by selecting options from a pre-defined dropdown list.

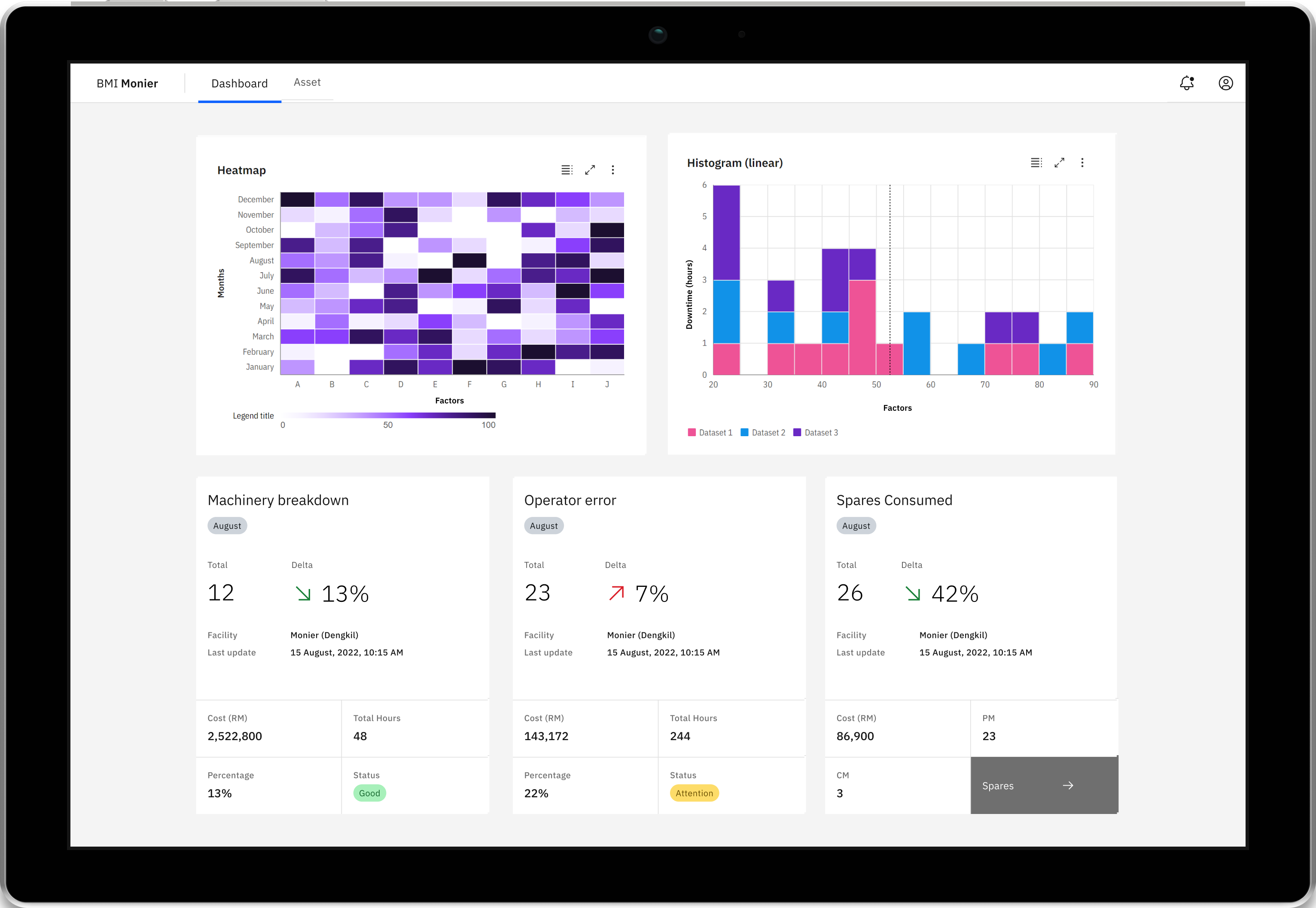

Dashboard

The data collected will then be used to provide a detailed analysis through a dedicated dashboard page. The dashboard will allow users to have a better understanding of downtime root causes and help them take actions to resolve the issues.

History

The data will be consilidated and archived for future reference.

QR Code

The assets can be assigned with QR code, scannable using an approved device (e.g., a tablet authorized/safe to be used in plant) to view the status of the asset or to instantly assign downtime to it.

Hardware

The hardware requirement will be discussed in further details with BMI Monier. By default, the application is designed to be responsive and compatible with any smart devices regardless of oprating system or screen size.

Execution plan

The execution plan is as follows:

- BMI Monier to accept the proposal and Magnus Code to start the project.

- Magnus Code to carry out the following:

- Finalize the requirements with BMI Monier.

- Design the solution and present the final design file for approval.

- Once design is approved, Magnus Code to start the development.

- Magnus Code to carry out the testing and implementation for acceptance.

- Magnus Code to carry out the training and handover to BMI Monier.

Agile development

During the development phase, Magnus Code will be in constant communication with BMI Monier to ensure that the requirements are met. Agile development of 2 week sprints will be used to ensure that the solution is meeting the requirements.

Project timeline

The project timeline is as follows:

- Project start

- Requirements gathering and design phase - 4 week

- Development phase - 11 weeks

- Testing phase - 4 weeks

- Deployment to production - 2 weeks

Where possible, Magnus Code will carry out the project in parallel to minimize the overall project duration.

Project Duration

Total duration for the project is approximately 15 weeks

Project cost

One time development fee

| Description | Price (MYR) |

|---|---|

| Project Management/ Requirement gathering | 3,500 |

| UI/UX Design and customization | 5,280 |

| Application development | 45,540 |

| Onboarding, deployment and training | 6,880 |

| Total | 61,200 |

Monthly subscription fee

| Description | Price (MYR) |

|---|---|

| Data storage | 1,200 |

| Data hosting | 1,500 |

| Computing | 1,100 |

| Server cost | 2,500 |

| Total | 6,300 |

Monthly subscription fee will include maintenance and upkeeping of the application. Magnus Code will be responsible in ensuring that the application is working as expected. A dedicated communication channel will be provided to BMI Monier to inform or solicitate advice regarding any issues related to the application.

Note

Hardware cost is not included and will be added upon finallizing project requirement with BMI Monier

Change request

BMI Monier can request for changes to the system at any point in time through the change request process. The change request process is as follows:

- BMI Monier to submit the change request to Magnus Code.

- Magnus Code to review the change request and provide a quote for the change request.

- BMI Monier to approve the quote and Magnus Code to carry out the change request.

Payment terms

Payment terms are as follows:

- 60% of the total cost is to be paid upfront.

- 20% of the payment is to be paid as the project progresses by milestone definition (2 week sprint - Agile).

- 20% of the payment is to be paid after the project is completed and deployed to production.

Monthly subscription fee is to be paid either on quarterly or yearly basis.